Fire and Chemical Protective Coverall for Offshore Oil and Gas Use

In the demanding and hazardous working environments of offshore oil and gas operations, the safety and protection of workers are paramount. High levels of risk from potential fire hazards and chemical exposures make it crucial to equip personnel with the best protective gear available. Among these, fire and chemical protective coveralls stand out as essential personal protective equipment (PPE). This article provides an overview of the key features, standards, and considerations when selecting fire and chemical protective coveralls for offshore oil and gas use.

Key Features of Fire and Chemical Protective Coveralls

Flame Resistance: These FR coveralls are made from materials that can withstand ignition and prevent the spread of flames. The material should not melt or drip, providing a barrier between the wearer and the fire.

Chemical Barrier: High-quality coveralls offer protection against a broad range of chemicals, including hydrocarbons and other substances commonly encountered in the oil and gas industry. This protection can come from the fabric itself or from a special coating applied to the material.

Durability and Wearability: The fabric must be durable to withstand the rigors of offshore work while also being breathable and lightweight to maintain wearer comfort over long periods.

Antistatic Properties: Given the potentially explosive atmospheres in offshore environments, the coveralls should have antistatic properties to prevent the build-up of static electricity.

Emergency Visibility: For safety in emergency situations, these coveralls often include high-visibility features such as reflective strips that make the wearer more visible, particularly in low light conditions.

Fire and Chemical Protective Coveralls Standards and Certifications

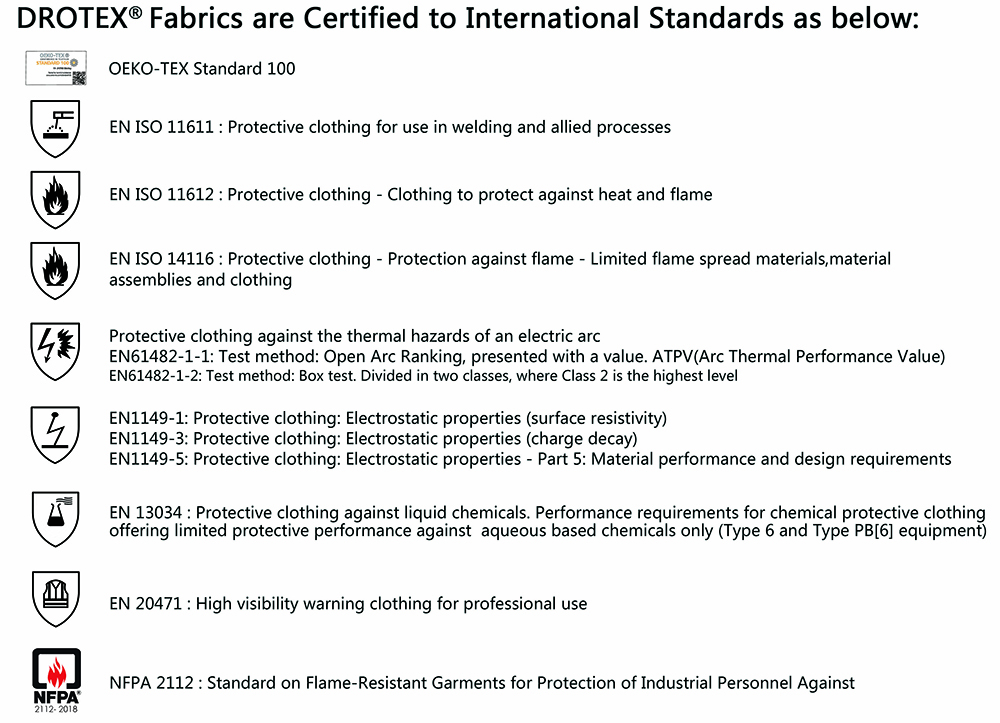

When selecting fire and chemical protective coveralls, it's crucial to look for products that meet internationally recognized standards and certifications. These may include:

EN ISO 11612: For protection against heat and flame.

EN ISO 1149-5: For electrostatic dissipative protective clothing.

EN 13034: For protection against liquid chemicals.

EN ISO 20471: For high visibility clothing.

Meeting these standards ensures that the coveralls offer a verified level of protection against the specific hazards encountered in offshore oil and gas operations.

Fire and chemical protective coveralls are a critical component of the protective gear for workers in the offshore oil and gas industry. Selecting the right coveralls requires a clear understanding of the hazards present, as well as considering comfort, durability, and compliance with relevant safety standards. By prioritizing these factors, employers can ensure that they provide their workforce with the highest level of protection possible, reducing the risk of injury in these high-risk environments.