Flame-retardant textiles have a wide range of applications, from the simplest clothing and toys on people to curtains, tents, and automotive fabrics for home decoration. Since entering the 21st century, flame-retardant fabric technology must not only meet today's strict flame-retardant standards, but also put forward strict requirements in terms of durability, strength, comfort, appearance, etc., and people are paying more and more attention to the effects of flame-retardant materials on the human body Due to the impact of health and eco-environmental protection, these flame-retardant fabrics are often in contact with human skin or in the same environment as humans for a long time. This makes the flame retardant technology of fibers and textiles face greater challenges.

In recent years, permanent flame-retardant fibers have received more and more attention due to their excellent flame-retardant properties and environmental protection.

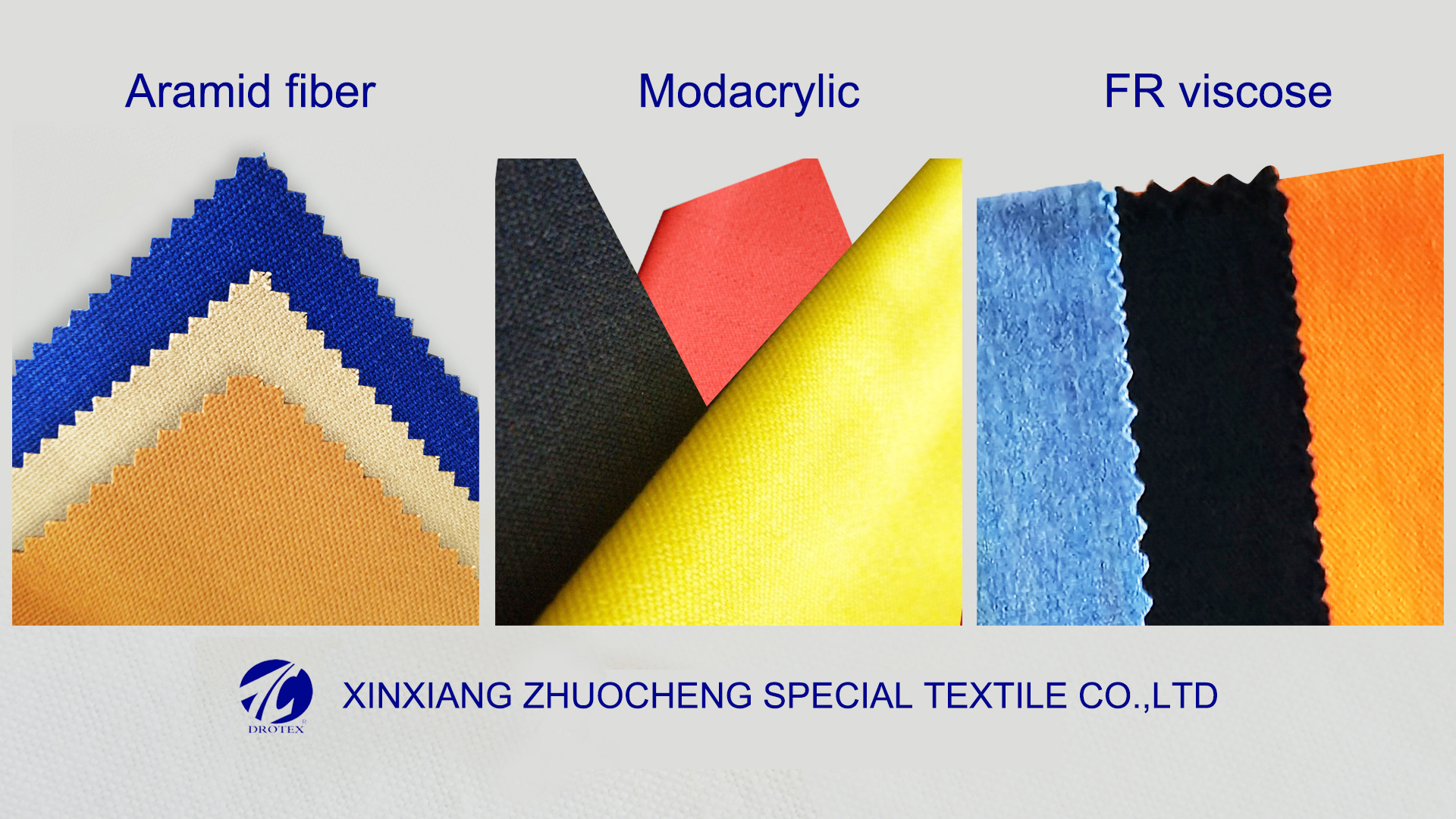

Aramid fiber

It includes two kinds of fibers: para-aramid and meta-aramid. Aramid is the most excellent high-performance fiber invented by DuPont.

Aramid fabrics are permanent flame-retardant fabrics. The flame-retardant performance will not decrease with the increase of washing times. It has permanent flame-retardant properties and will not melt under high temperature conditions, and has excellent thermal stability. The fabric has excellent flame-retardant performance, the continuous burning and smoldering time are less than 2 seconds; the fabric has high breaking and tearing strength, the fabric is light and breathable, and the clothing has a long service life; the fabric has excellent heat insulation performance after being burned in a fire, and has extremely smoke content Low, protect life safety to a greater extent. The main application areas of aramid include flame-retardant protective materials, high-temperature smoke and dust filter materials, and other technical textiles. Among them, flame-retardant protection includes military and police combat uniforms, fire-fighting clothing, rescue clothing, welding clothing, furnace clothing, petrochemical clothing, arc-proof clothing , Flame-retardant felts, sound-proof blankets and home flame-retardant textiles.

Modacrylic

Acrylic fiber has excellent flame retardant properties. The LOI is 34.Modification of acrylic fibers can be obtained by copolymerization flame-retardant modification, blending flame-retardant modification, thermal oxidation method, flame-retardant finishing and post-treatment flame-retardant modification. Nowadays, most industrialized products are woven by copolymerization.

FR viscose

Flame retardant viscose has the advantages of good comfort and environmental protection.

The flame retardant modification methods of viscose fiber mainly include grafting, blending and copolymerization. The blending method is currently a commonly used flame retardant method. The flame-retardant viscose fiber will not burn after being exposed to fire, forming a dense carbonized layer, which protects the fiber from oxygen and then self-rests. Since the cellulose fiber itself does not melt, the flame-retardant viscose fiber also has the effect of no dripping. Flame retardant viscose is the most environmentally friendly flame retardant fiber, which can be explained under natural conditions. There is no pollution during the production process.

With the promulgation and implementation of my country's environmental safety, flame-retardant regulations and standards, the market demand for flame-retardant fibers will increase. The flame-retardant fibers and textiles produced by Xinxiang Zhuocheng Textile Co., Ltd. will be better qualified for the role of fire protection guards.