THPC Treated Flame Retardant Fabric

November 28, 2024

The traditional Proban method uses the flame retardant THPC (Tetrahydroxymethylphosphonium Chloride), which is a white crystalline compound formed by the reaction of phosphine, formaldehyde, and hydrochloric acid at room temperature. The reaction equation is as follows:

THPC can react with cellulose fibers to form crosslinks between cellulose macromolecular chains. The initial finishing process was a simple immersion rolling baking, and the improved process added steps of ammonia fumigation and oxidation. The process flow is: immersion rolling → drying → ammonia fumigation → oxidation → water washing → drying。

THPC Treated Flame Retardant Fabric Advantages: Elevating Flame Retardant Properties

The core advantage of utilizing THPC (Tetrakis Hydroxymethyl Phosphonium Chloride) in fabric treatment lies in its superior flame retardant capabilities. By chemically bonding with the cellulose in the fabric, THPC treatment imparts a durable, flame-resistant quality, significantly reducing the risk of ignition and flame propagation. This proactive approach to fire safety is instrumental in mitigating risks, showcasing how forward-thinking solutions can lead to safer environments.

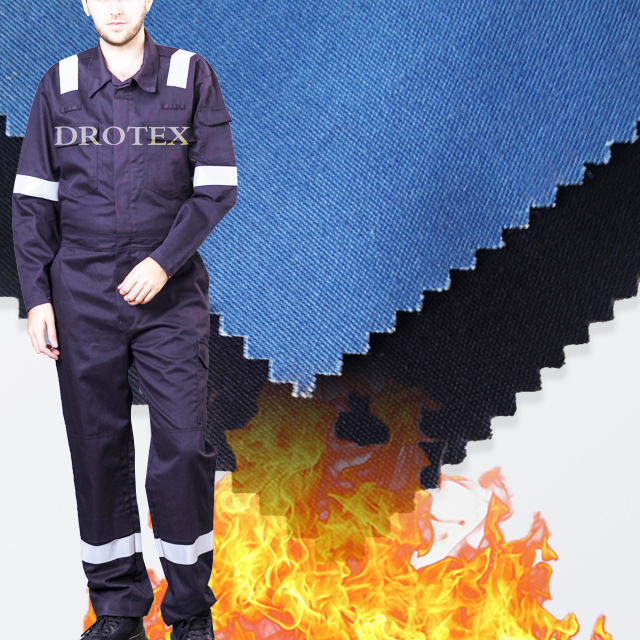

THPC Treated Flame Retardant Fabric Applications:Provide safety protection for workers

It is processed through special production technology to effectively prevent the spread of flames and protect the original properties of the fabric. This fr fabric has good durability and washing performance, is non-toxic and odorless, safe and reliable for human body, breathable and breathable, soft to the touch, and comfortable to wear.THPC treated fr fabrics are widely used in industries such as welding, petrochemicals, mining, and power to make workwear

| CFR220AS, 98% Cotton,2% anti static, twill, 220gsm | >3000Meters/color, USD3.2/M. Lead time 25-30 days. |