DROTEX Flame Resistant Apparel

Flame-resistant FR apparel is critical for protecting workers in high-risk environments where exposure to fire, sparks, arc flashes, or extreme heat is a concern. Below is a detailed breakdown of key categories, standards, materials, and design features, along with maintenance guidelines and supplier insights:

1. Welding Coveralls

Purpose: Protect against sparks, spatter, and radiant heat during welding and cutting.

Standards:

EN ISO 11611 (welding-specific flame resistance) .

EN ISO 11612 (heat and flame protection) .

Materials:

Aramid blends for high heat resistance.

FR-treated cotton for breathability and comfort.

Design Features:

Reinforced knees and elbows.

Flame-resistant zippers and Velcro closures.

High-collared design to protect the neck.

Reflective tape for visibility in low-light conditions

2. Mining Workwear

Purpose: Shield against sparks, static electricity, and abrasive hazards in mining operations.

Standards:

EN 14116 (limited flame spread) .

EN ISO 11612 (heat and flame protection).

EN1149

Materials:

FR-treated cotton or aramid modacrylic for durability and comfort.

Anti-static Fiber

Design Features:

Heavy-duty stitching for rugged use.

Multiple pockets for tools.

High-visibility colors or reflective strips for safety in low-light environments.

3. Oil & Gas Coveralls

Purpose: Guard against flash fires, chemical splashes, and arc flashes in oil rigs and refineries.

Standards:

NFPA 2112 (flash fire protection) .

EN ISO 11612 (heat and flame protection).

EN13034

Materials:

FR cotton or Aramid for flame resistance.

Chemical-resistant

Design Features:

Concealed snaps or zippers to prevent snagging.

Reinforced seams and stress points.

Built-in ventilation for breathability in hot environments.

4.Electrical Workwear

Purpose: Protect against arc flashes and electrical burns in power generation and maintenance.

Standards:

NFPA 70E (arc flash protection) .

ASTM F1506 (arc-rated fabric performance) .

Materials:

Aramid blends for arc resistance.

Modacrylic for lightweight comfort.

FR-treated Cotton Nylon blends

Design Features:

Arc-rated labels indicating ATPV (Arc Thermal Performance Value).

Loose-fitting design to allow air circulation.

Flame-resistant buttons and closures.

5.Offshore Clothing

Purpose: Provide flame resistant waterproof protection in maritime and offshore oil platforms.

Standards:

EN ISO 11612 (heat and flame protection).

EN 343 (waterproof and breathable) .

In offshore operations such as offshore oil platforms, ships, offshore wind power, etc., the risks faced by different types of work vary significantly. Therefore, protective clothing needs to be tailored to the specific operating environment Customize the design of hazards and functional requirements.

6. Boiler Suits

Purpose: Offer full-body protection against heat, sparks, and abrasions in industrial settings.

Standards:

EN ISO 11612 (heat and flame protection).

EN 14116 (limited flame spread).

Materials:

FR-treated cotton or aramid blends.

Design Features:

One-piece design with elasticated cuffs and waist.

Multiple pockets for tools.

Flame-resistant zippers and Velcro closures.

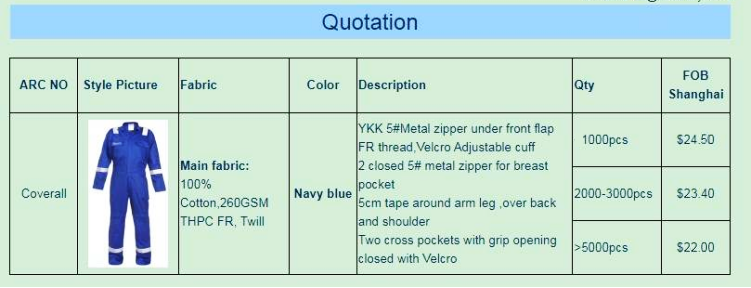

Flame Resistant Apparel Price