Flame Retardant Reflective Coverall Australian Style

Commonly used fabrics Details

100% Cotton Drill 240gsm

48% FR Modacrylic 37% Lyocell 15% Aramid 7oz

FR Modacrylic Lyocell Aramid 197 gsm

Oil-gas industry, welding,mine, metallurgy, traffic, airline, paint, electrical power etc industries.

* Packaging: one plastic bag for each set,20sets~40sets in one carton or customize.

* Shipping: by sea,by air,by express delivery.

Working in an oil refinery can be a challenging task, especially when it comes to safety. Safety gear, such as fire-resistant high visibility oil refinery workwear coveralls, is essential for ensuring the well-being of workers. These coveralls provide a protective layer and prevent any damage to the skin or clothing caused by chemicals, flames, or sparks.

Drotex is a trusted brand when it comes to high-quality safety clothing, and their fire-resistant high visibility oil refinery workwear coveralls are no exception. These coveralls are made from high-quality materials that are resistant to fire and provide excellent visibility. Drotex's coveralls also come with reflective strips to make it easier for workers to be seen in low light conditions.

Marketing with Drotex branding plays a vital role in promoting these coveralls and reaching out to potential customers. Drotex has been in the safety clothing industry for a long time and is a well-known name among people who require protective gear. Their branding and marketing efforts emphasize the safety features, quality, and durability of their products.

In conclusion, oil refinery workers need to take the necessary precautions to protect themselves from potential hazards. Fire-resistant high visibility oil refinery workwear coveralls from Drotex can provide the required safety features needed in a hazardous work environment. And buyers can be confident that Drotex's branding ensures a quality and reliable product. These coveralls are an investment that will pay off in the long run by providing workers with protection and peace of mind.

EN11611: Protective clothing for use in welding and allied processes

EN11612: Protective clothing. Clothing to protect against heat and flame

EN ISO 14116: Protective clothing - Protection against fame - Limited flame spread materials,material assemblies and clothing

Protective clothing against the thermal hazards of an electric arc

EN61482-1-1: Test method: Open Arc Ranking, presented with a value. ATPV(Arc Thermal Performance Value)

EN61482-1-2: Test method: Box test. Divided in two classes, where Class 2 is the highest level

EN1149-1: Protective clothing: Electrostatic properties (surface resistivity)

EN1149-3: Protective clothing: Electrostatic properties (charge decay)

EN1149-5: Protective clothing: Electrostatic properties - Part 5: Material performance and design requirements

EN 13034 : Protective clothing against liguid chemicals. Performance reguirements for chemical protective clothing offering limited protective performance against aqueous based chemicals only (Type 6 and Type PB6) equipment)

EN 20471 : High visibility warning clothing for professional use

NFPA 2112 : Standard on Flame-Resistant Garments for Protection of Industrial Personnel Against

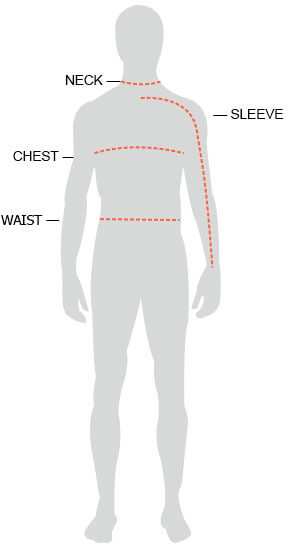

| MEN’S | SIZE | CHEST | WAIST | |||

| S | 34 | 36 | 39.5 | 41 | 34 | 35 |

| M | 38 | 40 | 42 | 43 | 36 | 37 |

| L | 42 | 44 | 45.5 | 47.5 | 40 | 42 |

| XL | 46 | 48 | 50 | 52 | 44.5 | 47 |

| 2XL | 50 | 52 | 54.5 | 56.5 | 50 | 52.5 |

| 3XL | 54 | 56 | 58.5 | 61 | 55 | 57.5 |

| 4XL | 58 | 60 | 63 | 65 | 59 | 61 |

| 5XL | 62 | - | 67 | - | 63 | - |

If you need our products please write down any questions, we will reply as soon as possible.